National Cambridge Collectors, Inc.

A non-profit 501(c)(3) organization.

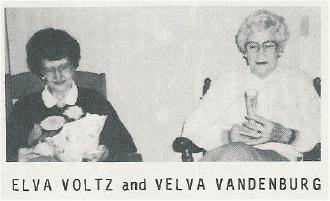

Workers of the Month, Voltz & Vandenburg

by J. D. Hanes - Issue #215 March 1991

We were pleased to have as our former workers for this month, Elva Voltz and Velva Vandenburg. These two ladies are twin sisters, and both worked at the Cambridge Glass factory for approximately 35 years each.

Velva and Elva started at the factory after

graduating from school at the age of 16, in 1923. Their boss was

Mr. D. E. Martin, who at that time was head of the Decorating

Department. Their first job in that department was the removal of

excess gold from the pieces of glass. Elva stated that when they

started, gold decorating was still in an experimental stage. She

also told us that their brother thought they would like it better

working at the pottery, however, Mr. Martin told them that if

they would stay, he would teach them how to decorate.

Velva and Elva started at the factory after

graduating from school at the age of 16, in 1923. Their boss was

Mr. D. E. Martin, who at that time was head of the Decorating

Department. Their first job in that department was the removal of

excess gold from the pieces of glass. Elva stated that when they

started, gold decorating was still in an experimental stage. She

also told us that their brother thought they would like it better

working at the pottery, however, Mr. Martin told them that if

they would stay, he would teach them how to decorate.

In the beginning, they told us that gold removal was done with a piece of wood and was very difficult to do. Later, they tried a safety razor blade, but it was too stiff to do the work correctly. Finally they started to use a double edge razor blade that had one edge wrapped in cloth that had been fed through the hole in the center and wrapped around the blade not in use. Needless to say, all cloths and blades were turned in so that the gold could be reclaimed from them.

They also told us that to get your gold or whatever metal you were using to decorate with, was a process in itself! You were required to sign out for the gold and you were carefully watched. At the end of the day, you were then required to return everything, including the working tools and cloths.

In the early years, before the Decorating Department addition to the factory, the glass was fired in a kiln to adhere the gold to the glass. After the addition was put on, a lehr was built for this purpose. The ladies thought that this addition was put on in 1925 or 1926. They stated that the addition was nice for the extra light, but it was very cold in winter.

The ladies then explained about the different brushes and techniques used to paint gold on the glass. The gold was 24KT in a paste and was thinned with what they thought was turpentine. After the turpentine had been used for awhile, for thinning the paste, another solution was tried, but they could not remember what it was.

Other metals they remembered using on the glass were: sterling silver, white gold, platinum and bright gold. According to them, bright gold, which was cheaper gold that the gold paste, was very difficult to use. Platinum was hard to use also. To do the platinum work the piece had to have a "red mud" put on where the platinum was to go. The piece was put through the lehr to bake the mud on. Then the mud was removed and platinum applied. They remembered using the platinum and bright gold on stemware mostly.

When asked, they said that they did do some silk screen work, but not much. There were men in the department also, and they did very good work, according to the ladies. Walter Guegold, who many of you know as the maker of etching plates, was very talented and did work on freehand gold decorations.

When asked about enamel decorations, they remembered them from very early in their time at the factory. They remembered doing the Japonica decoration, but not a lot of it. When asked if they remembered doing much gold work on Rosepoint in carmen, they said they did do quite a bit, however, during the war not much carmen was made due to material shortages. Asked if they knew what companies or stores they were decorating for, the only big one they could remember was Farber Bros.

Many of you may remember these ladies from last year's Former Workers Reunion, held during Convention. They are delightful and were a joy to have as our guests.