National Cambridge Collectors, Inc.

A non-profit 501(c)(3) organization.

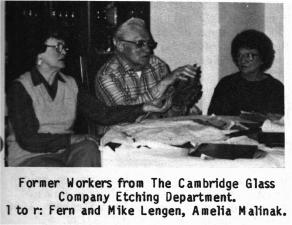

Former Worker Interview: Mike & Fern Lengen and Amelia Malinak

by Lorraine Weinman

Issue No. 194 - June 1989

Former Workers of the Month tell how it was done back then.

During the April 1989 meeting of the Cambridge Cordials Study Group, an interview was conducted with Mike and Fern Lengen and Amelia Malinak, former Etching Department workers at The Cambridge Glass Co. This was the second such interview and videotaping conducted by the Cordials for future use by members of N.C.C., Inc.

Amelia Malinak worked in the Etching Department as a "put-on" girl from 1927 until the first closing of the company in 1954 and returned when the company reopened. Fern Lengen worked from 1941 until the first closing and also was a "put-on" girl. Mike Lengen worked as a printer in the same department from 1943 until the first closing and returned during the reopened period.

Fern and Amelia described the typical setting in the Etching

Department. In particular, they discussed their shop. At one time there

were eight shops, but that number went down to four. Within each shop

there were four or five girls at a table and a printer. The printer sat

at his table with his back to the girls.

Fern and Amelia described the typical setting in the Etching

Department. In particular, they discussed their shop. At one time there

were eight shops, but that number went down to four. Within each shop

there were four or five girls at a table and a printer. The printer sat

at his table with his back to the girls.

Mike illustrated the printer's work with some tools and plates that were typical of those used. He showed the setup of the plates and demonstrated how the paper was cut, ink put on the plates, the paper rubbed down onto the inked surface, and how it was lifted off. This paper was then handed to the "cut-out" girl who sat behind the printer, at the table with the remainder of the shop.

The cut-out girl would then cut the pattern out and hand it to one of the put-on girls. She would then hold the piece in her right hand and put the paper on with her left hand. When she was done, the piece was then passed on to one of the "rub-down" girls. The three workers concurred that the rub-down girls had the hardest job.

The glass was then dipped in alcohol and water and the tissue peeled off with the print remaining on the glass. At this point, it was sent to the paint shop, to have wax applied, before being subjected to acid.

Mike also described, in detail, the ink that was used and the process to create good ink. He explained the uses of hydrofluoric acid, versus sulfuric acid, in the etching process.

All three workers decided that the #3121 line was probably the easiest line to do, with a yield of between 10 and 15 dozen an hour. It was stated that the #3500 line was hard to work on.

They discussed numerous patterns on which they worked, individual likes and dislikes, making the prints fit each piece, the weather's effect on their work and unique facts about working at the Cambridge Glass Company.

All of this extremely interesting information will eventually be available on videotape through N.C.C., Inc.