National Cambridge Collectors, Inc.

A non-profit 501(c)(3) organization.

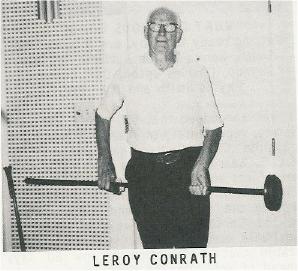

Worker of the Month, Leroy Conrath

by Cindy Arent - Issue #221 September 1991

It has been several months since the Cordials Study Group has

been able to interview a former worker of the Cambridge Glass

Company. However, because of the Workers Reunion, during

Convention, we were very fortunate to interview and video tape,

two brothers, Leroy and Harold Conrath, from the hot metal

department. Since we taped two workers, we will make the most of

it and split the article into two parts. This month's article

will describe a few of the jobs that Leroy did in the hot metal

department, and next month we will hear from his younger brother,

Harold.

Company. However, because of the Workers Reunion, during

Convention, we were very fortunate to interview and video tape,

two brothers, Leroy and Harold Conrath, from the hot metal

department. Since we taped two workers, we will make the most of

it and split the article into two parts. This month's article

will describe a few of the jobs that Leroy did in the hot metal

department, and next month we will hear from his younger brother,

Harold.

The Conrath family moved to Cambridge from Marietta, Ohio, with the specific purpose of working at the Cambridge Glass Company. Leroy's father had already been a glass worker at a glass plant in Marietta. He mentioned that Orie Mosser, foreman of the hot metal department, had also moved to Cambridge from Marietta and that other workers had come from Findlay, Ohio.

1923 was the year that Leroy began working at the Cambridge Glass Company. He worked part-time for two summers until his 16th birthday, when Orie Mosser sent him home at noon to get his birth certificate. He was employed full-time after that.

One of Leroy's first jobs was holding paste or "water" molds

for the blowers in a vase shop. He later moved up to the more

skilled position of gatherer. The largest pieces of ware that he

remembers gathering were the Swan punch bowl and the Cascade

punch bowl. It took two gatherers with different sized rods to

gather the Swan punch bowl. The first man would gather about nine

or ten pounds of glass, while the second would only gather enough

for the neck and head.

One of Leroy's first jobs was holding paste or "water" molds

for the blowers in a vase shop. He later moved up to the more

skilled position of gatherer. The largest pieces of ware that he

remembers gathering were the Swan punch bowl and the Cascade

punch bowl. It took two gatherers with different sized rods to

gather the Swan punch bowl. The first man would gather about nine

or ten pounds of glass, while the second would only gather enough

for the neck and head.

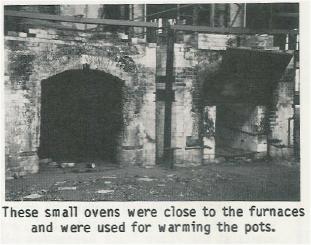

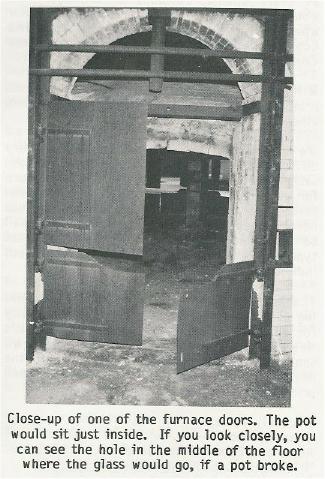

Leroy also mentioned that he worked "on the floor," for five

or six years, tending the furnaces. He described in detail how

the new pots for the furnaces would arrive on the box cars and

how they were carefully unloaded and prepared for use. Before

each pot could be used, he would glaze the inside with glass

using a long bent rod. Orie Mosser would personally check each

pot to be sure that the entire interior had been glazed and then

they would ladle out the excess glass. The pot then had to be

warmed in one of the mold ovens before being placed in the

furnace for use. Leroy also said that if a pot would break while

in the furnace, the men downstairs would turn on a special burner

so that the glass could flow more easily down to the basement

through a hole in the furnace floor. When the glass cooled,

the labor crew would use picks to break it

up and haul it to the dump.

pot to be sure that the entire interior had been glazed and then

they would ladle out the excess glass. The pot then had to be

warmed in one of the mold ovens before being placed in the

furnace for use. Leroy also said that if a pot would break while

in the furnace, the men downstairs would turn on a special burner

so that the glass could flow more easily down to the basement

through a hole in the furnace floor. When the glass cooled,

the labor crew would use picks to break it

up and haul it to the dump.

If a pot would crack during use, many times, Leroy would attempt to repair it through a process he called "muddying it up." He would go in Saturday morning and cover the damaged area with mud. Then, using a broom, he would cover the mud with whitewash which made it hard.

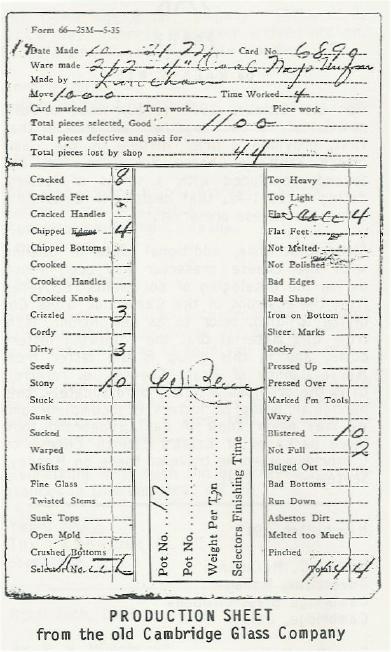

It is impossible to include all of the information that Leroy shared with us. He brought one of his "Production Sheets" to the interview. As you can see (below), he and his shop made 1144 pieces of ware in four hours. Of these pieces, only 44 were discarded by the selector.

This sheet is very interesting because of the various terms

used by the company to describe the bad pieces. I think that my

favorite is "flat feet." Leroy has donated this production sheet

to our Museum, along with a small calendar book with the

Cambridge Glass logo on it. The company gave out these books and

Leroy used his to mark down a variety of information, from

tallies of ware made and workers names, to scores of horseshoe

games.

favorite is "flat feet." Leroy has donated this production sheet

to our Museum, along with a small calendar book with the

Cambridge Glass logo on it. The company gave out these books and

Leroy used his to mark down a variety of information, from

tallies of ware made and workers names, to scores of horseshoe

games.

Leroy continued to work at the Cambridge Glass Company until the final closing, and then went on to work at the Variety Glass Company. He has may interesting facts and stories to share. The tapes will be available at the Museum in the near future.