National Cambridge Collectors, Inc.

A non-profit 501(c)(3) organization.

A Brief History of the Cambridge Glass Company

by Mark Nye

The Cambridge Glass Company came into being for two main reasons:

the desire of the citizens of Cambridge, Ohio, to secure a new industry

for their city and the desire of a location for a new glass plant being

planned for by the National Glass Company, based in Pittsburgh,

Pennsylvania. The site would have to be near sources of natural gas and

coal, both of which Cambridge had. The citizens of Cambridge were

represented by the Cambridge Improvement Company. In 1901, the two

parties came to an agreement. The citizens of Cambridge would provide

the site and National Glass Company would build the factory which it

would own.

Pennsylvania. The site would have to be near sources of natural gas and

coal, both of which Cambridge had. The citizens of Cambridge were

represented by the Cambridge Improvement Company. In 1901, the two

parties came to an agreement. The citizens of Cambridge would provide

the site and National Glass Company would build the factory which it

would own.

To open the factory, a new company, The Cambridge Glass Company was incorporated by five individuals. Three men associated with National: Myron Case. Andrew Heron, Addison Thompson; and two local individuals: Fred Rosemond and Casey Norris.

After construction began, National went looking for an individual to run the plant and head the newly formed Cambridge Glass Co. They selected Arthur J. Bennett, a native of England but a long time resident of the United States. Mr. Bennett's background was in the field of importation and retailing of European china and glassware and was well known in the New York and Boston areas.

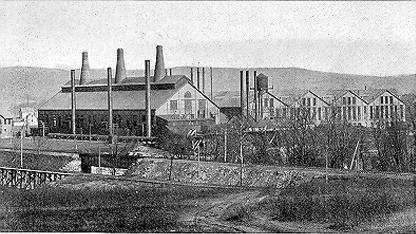

Construction of the plant was completed in early 1902 and in May of that year the first piece of glass, a pitcher, was produced. During the first years the ware produced by the Cambridge Glass Co. came from molds previously used by other glass companies and was typical of the glassware of the period: table sets, jugs, bowls, molasses jugs, jars, tumblers and lamps.

It was not until 1904 that the first original Cambridge line, Radium, was designed and produced. The year 1904 also saw the introduction of the first Cambridge trademark: NEARCUT. Pressed into the glass, it was also used as two words, one above the other.

From the very beginning, the Cambridge Glass Co. was an independent company that leased its facilities from the National Glass Co. Indications are that by 19O6 Mr. Bennett was the principal stockholder and hence the owner of the Cambridge Glass Co, but still did not own the physical plant.

1907 saw the financial collapse of the National Glass Company but this had no effect on the operations of the Cambridge Glass Co. and facility lease payments continued to be paid to National and its receivers. After three years of legal and financial proceeding that dissolved the National Glass Co., the Cambridge Glass Company was able to purchase the buildings in which it was operating. Now, eight years after it made its first piece of glass, Cambridge Glass Company was a completely independent company whose principal stockholder was Arthur J. Bennett. The company prospered under his ownership and around 1910 acquired the rights to the idle factory of the former Byesville Glass and Lamp Co. and expanded its operations into that plant, located a few miles south of Cambridge.

Through the early years the company operated its own coal mines and consumed many tons daily producing raw gas to fire its melting pots. In addition to the gas it produced, the factory used natural gas from its own wells and also bought gas from other well owners.

By 1920, the trend was away from the heavy pressed and imitation cut

glass and toward lighter pressed and blown ware. Also by this time

several etchings had entered the Cambridge line, among them Marjorie,

named after Mr. Bennett's daughter. The early 1920s saw all operations

stopped at the Byesville plant with all work now being done at the main

plant in Cambridge. At the beginning of 1922, a new trade mark, the now

familiar letter C enclosed in a triangle, was introduced. During the

early to middle 1920s a variety of opaque colors were brought into the

Cambridge line, most being produced for only one to three years. Later

in the 1920s transparent colors became very popular, replacing the

opaques. Complete dinnerware lines, plain and etched, were being sold

as was a large selection of decorative and accessory items. The company

continued to produce a complete line of pharmaceutical items, a line

that was continued until 1954 when the original company ceased

operations.

named after Mr. Bennett's daughter. The early 1920s saw all operations

stopped at the Byesville plant with all work now being done at the main

plant in Cambridge. At the beginning of 1922, a new trade mark, the now

familiar letter C enclosed in a triangle, was introduced. During the

early to middle 1920s a variety of opaque colors were brought into the

Cambridge line, most being produced for only one to three years. Later

in the 1920s transparent colors became very popular, replacing the

opaques. Complete dinnerware lines, plain and etched, were being sold

as was a large selection of decorative and accessory items. The company

continued to produce a complete line of pharmaceutical items, a line

that was continued until 1954 when the original company ceased

operations.

The 1930s were prolific years. Colors such as Carmen, Royal Blue,

Crown Tuscan, Heatherbloom and Forest Green were developed and brought

to market. New dinnerware lines and numerous new etchings including

Rose Point, became part of the Cambridge line. All this took place in

spite of the effects the Great Depression had on company

operations.

to market. New dinnerware lines and numerous new etchings including

Rose Point, became part of the Cambridge line. All this took place in

spite of the effects the Great Depression had on company

operations.

During its peak years, Cambridge had as many as 700 employees working three shifts with all three furnaces running at full blast. Mr. Bennett continued as company president; his son-in-law, Wilber L. Orme, was vice-president; William C. McCartney was corporate secretary and sales manager; G. Roy Boyd Was treasurer and J. C. Kelly kept the plant running as factory superintendent. In July 1939, Mr. Bennett sold his controlling interest in the company to his son-in-law, Wilber L. Orme. Mr. Bennett continued as company president until his death in February 1940.

Mr. Orme continued to develop new lines and colors. In 1950, Cambridge's Square Pattern won top honors across the United States for its modem design. Soon, however, the demand for fine handmade glassware began to decrease and at the same time, competition from foreign and machine-made glass began taking its toll. In 1954, Mr. Orme decided to close the plant, ending one of the best and most prosperous glass companies the world has ever known.

Shortly after it ceased operations, the company was sold to a firm headed by Sidney Albert of Akron, Ohio. The plant reopened in March 1955. Sales were poor and in l956 Morrison Industries Inc., of Cleveland, Ohio, acquired possession. Sales continued to be slow and management problems grew. The company closed its doors for the final time at the end of l958. In November 1960, Imperial Glass Co. of Bellaire, Ohio, acquired the remaining assets, exclusive of the physical plant. Included in the sale to Imperial was all remaining stock, molds, etching plates and portable equipment. For a time in the l96Os, Imperial did produce Cambridge by Imperial but sales were not what was expected and the lines were discontinued.

1984 saw Imperial forced into bankruptcy and eventual liquidation of all its assets. At that time National Cambridge Collectors purchased a number of the remaining significant molds, all of the etching plates, except those for Rose Point, and other Cambridge related equipment. Glass companies such as Fenton Art Glass and the now defunct Summit Art Glass also acquired Cambridge molds.

Prior to use, Fenton altered the molds they purchased thus causing no major problems for collectors. Summit Art Glass did not and a wide array of reproductions entered the market place. Many of the pieces produced by Summit were in colors never used by Cambridge. However, some were and a few continue to cause confusion for Cambridge collectors. The Rose Point etching plates were never used and were subsequently acquired by NCC, Inc.

In 2006 NCC Inc. was able to acquire all the Cambridge molds owned by Summit Art Glass. A few insignificant Cambridge molds remain in private hands but these offer no significant problems for today's collectors. The Cambridge molds that still remained following the Imperial liquidation were sold for scrap iron.

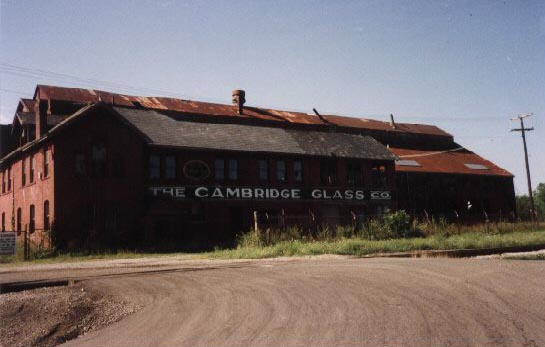

The Cambridge Glass Co. factory buildings met their demise in 1989 when the owner decided they had deteriorated beyond repair and were hazardous. All that remains today is a weed-filled field, a sad sight to see if you were fortunate enough to have seen the factory with its many artisans and laborers busy at their trade.