Turn Tickets: Insights Into the Business of Glass Making - Part I

by Tarzan Deel

Issue No. 266 - June 1995

The Non-Glass Committee has been cataloging and restoring to the degree possible, numerous paper items that remain as part of the history and heritage of the Cambridge Glass Company. Many of these add new insights to the production process and shed light on the business success or failure of the factory.

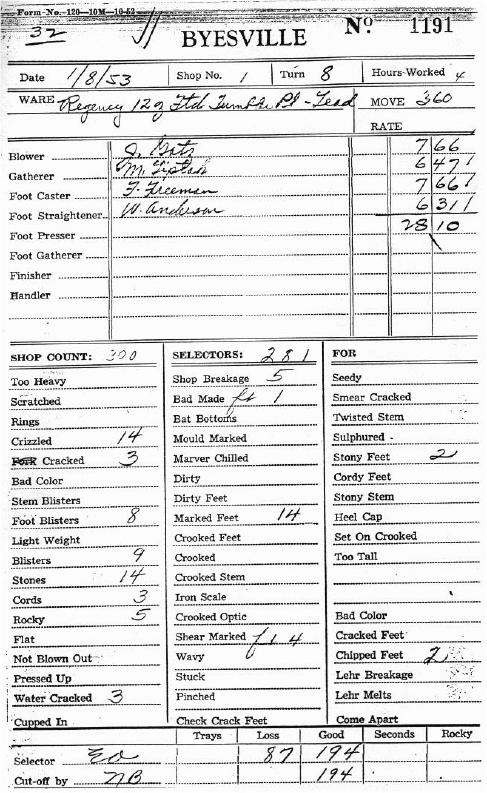

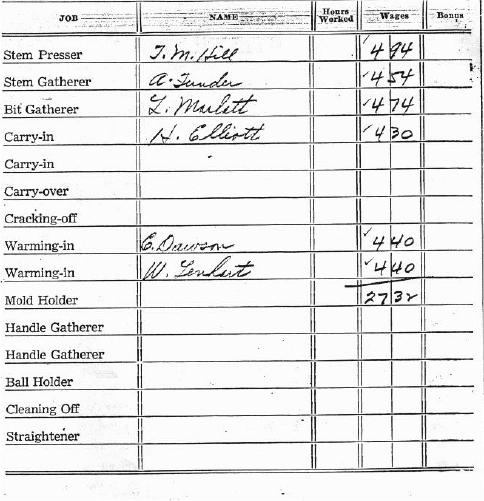

Turn tickets provide history of a typical production shift. They indicate what was produced, by whom, and the quantity of the item that was successfully made and what had to be repaired or junked. Of all the documents NCC possesses, the Turn Card/Turn Ticket(s) are among the most interesting. The club has only a limited number of these records as the Company did not feel the need to keep them. Most of what does exist, dates to the 1950's.

Over the next few months, we will publish some of these turn tickets to give you insights on the glass making process. You may be astounded by how much product was destroyed. The success rate was dismal compared to today's manufacturing standards. However, we must bear in mind that this was handmade glass. It's fragility was extreme. Glass making was truly an art, one our club members respect and acknowledge. In the next Crystal Balls we'll add definition to the terms on the turn tickets.

What is a Turn Card/Turn Ticket? A turn is a four hour shift which represented a "move" for a particular product. The move will depend on what the product is. A larger item will take longer and thus, less is produced. If problems occur, the "move" may not be completed but it will still be a turn (or a production cycle in today's terms).

Byesville Cards? You'll notice Byesville on some of the tickets. These were the remaining inventory which Cambridge used after the Byesville plant closed, until of course, the Cambridge Glass Company went out of business. We have been able to locate large quantities of blank turn cards. Either they ordered too many cards in inventory or they expected to be in business longer than the fates permitted.

The O. M. German System? We don't know, but are investigating.

What do all the terms on the turn ticket mean? Let's go one at a time (more next month):

Date: Obvious.

Shop No.: This is the area of the factory floor performing the work.

Turn: This is the number of the turn. If the product had been run before in the same production period, then the number would be increased for each turn run.

Hours worked: Almost always four hours unless their were production problems.

Ware: The item produced. The item number, description and color are often provided on this line.

Move: This is the number of items expected to be produced on this turn.

Blower: When the item was blown, the name of the blower and his rate is provided (check out the wages!)

Gatherer: Almost all production had a gatherer, the name and rate were listed.

Foot caster: If the item had an applied foot, then a foot caster was used.

Foot presser and gatherer: same as above.

Finisher: All items had a degree of finishing. Some required more effort and a specific finisher was assigned.

Handler: This was the person who applied a handle to a handled item. The name and rate were listed.

Card No. 1191: The item was a Regency 12 oz. footed tumbler in crystal with no etching. The normal "move" 360 but only 300 were produced on this turn. Of those, 29 were scrapped on the production floor and 87 more were rejected for several reasons noted on the card. [Card shown at end of article]

Given this was the 8th turn of this item, the failure rate is surprising. If we can find the other turn tickets maybe we can piece together this 1953 story and what insight it might provide on why the company failed. Of course, one piece cannot make a company fail, but if the trend was similar with other lines it sheds light on the downhill slide of Cambridge's business. More later ...